Do you have specific questions or require industrial or mobile applications outside of the Benelux? Contacting DC Solar Systems is always a good idea!

Images worth a

1000 words

Video

Quality cells combined with high-quality European solar glass and a sturdy frame make DC Solar Systems modules virtually immune to micro-cracks in real-world conditions.

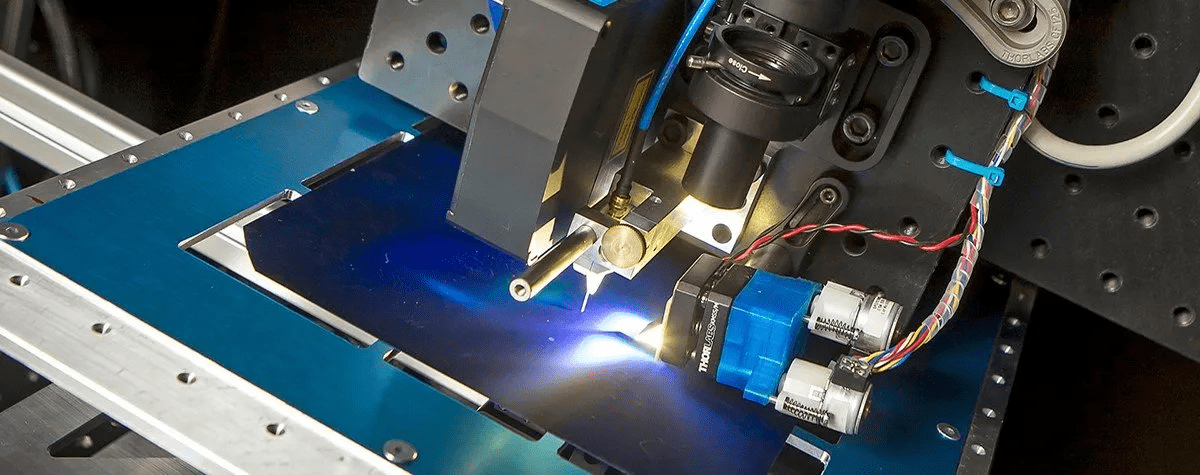

Micro cracks are small cracks in solar cells. They are impossible to see with the bare eye, but truly impact the performance of a PV system. A feared enemy of traditional (busbarred or wired) modules.

Most solar cells are comprised of very thin silicon wafers, usually around 0.15-0.20 mm thick. These have some ability to flex, but simple pressure or stress can induce micro-cracks. Newbies in solar industry often unknowingly create micro-cracks by throwing boxes of gear on top of stacked panels. Standing or kneeling on panels during installation is also a contributor to micro-cracks.

DC Solar Systems back contact modules are more robust than conventional modules because of the integrated Conductive Backsheet (CBS). This innovative copper design ensures optimal contact with an incredible number of contact points across the entire cell. It is an additional (metal) environmental barrier to protect the cells and keep them sturdily in place, and actually strengthens the contacting architecture.

If a micro-crack should occur, the cell will still be in perfect contact with the copper that conducts the energy, effectively designing the negative effects of microcracks out of the module.

Image: TNO Research

Nearly half the world’s supply of silicon cells, a key component used in the solar power industry, is likely to depend on forced labour. Obviously, this won’t be called forced labour, let alone slavery. More likely are mystic names, like surplus labour and labour transfer programmes. By selecting almost unrealisatic low-priced non-Western mass produced PV, customers unknowingly support these practices.

At DC Solar Systems, we care. We source our materials smartly. Whenever possible, we prefer around the corner, made in Europe. Which by the way also results in a significant lower carbon footprint.

Where the more complex supply chains came in, we’ve carried out (or participated in external) research to increase our understanding and knowledge to the maximum extent. Creating insight is a mandatory standard of our sourcing process. We will never shy away from sensitivities: no forced labour simply is a spec. This brings us peace as well.

Image: Sheffield Hallam University, United Kingdom

At DC Solar Systems we only use the original Stäubli MC4 connectors to ensure that your installation is as safe as possible.

MC4 Connectors are a small but important component of the solar installation. There are many benefits of genuine MC4 connectors, however with so many cheap copies available today, remember original MC4 connectors are used to reduce the risk of overheating which could lead to a fire.

For those who didn’t know yet, MC4 stands for the Swiss manufacturer Stäubli Multi-Contact and size (4mm2) of the contact assembly pin. MC4 Connectors have been used to equip almost all solar panels for the last decade.

While it may seem difficult to distinguish a genuine MC4 connector from a copy, the technical comparisons -and risks- differ greatly. Using different brands can result in poor connections, possibly resulting in:

So, no doubt: at DC Solar Systems you can be sure you will get the benefits and the safety of original MC4 connects.

Image: Stäubli

Video

We are so proud to describe our brand new production facilities. Imagine what 30 frames a second would do. Let’s replace 2.640.000 words for you, just by clicking a play-button.

Modules

Full black solar modules with an impressive power harvest per m2 (sqft). When every square meter of roof surface counts (and when doesn’t it).

From 1.8 kg/m2 and up, depending on the need or application. While maintaining the proven and highest power harvest per m2 (sqft).

WE are

Do you have specific questions or require industrial or mobile applications outside of the Benelux? Contacting DC Solar Systems is always a good idea!